Poor soil conditions are many times the greatest risk and cost for a project. Undercutting (removing unsuitable soil and replacing with suitable soil from offsite) sites can be very costly and dependent upon suitable weather and moisture content.

Aggregate piers provide an economical alternative to address poor soil conditions where required bearing capacities can’t be met using the native soil or uncompacted previous fill. The process is cheaper and faster than total soil replacement, as well as less dependent on weather. The site is prepared to the proposed subgrade elevation and aggregate piers are installed below the foundation elements.

Some of the more well known systems are Geopier or Vibro Stone columns. There are various types of installation processes, but the main two are drilled or vibrated columns. Drilled systems remove the soil via augering and layers of stone are placed and compacted in lifts until reaching the desired elevation.

Vibrated columns displace the soft soil to form the hole and are either “bottom fed” or “top fed”. Top fed systems are used in cohesive soils where the walls of the holes will hold shape without collapsing. After the holes are formed, stone is dumped in roughly two foot lifts and vibrated to the required compaction.

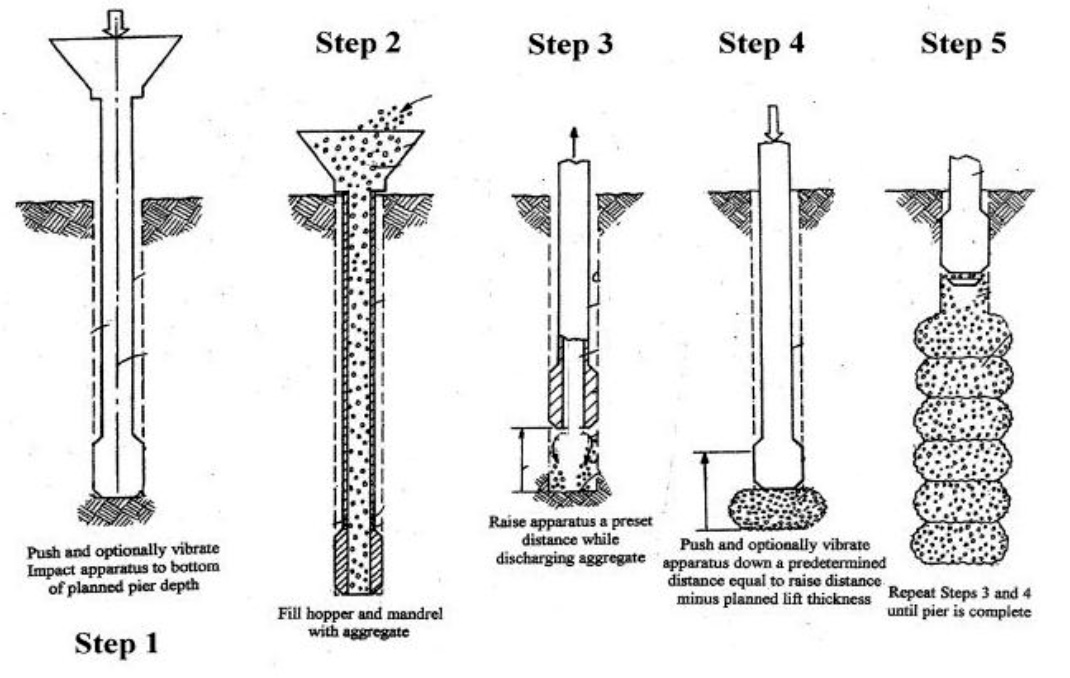

Bottom fed systems are used in unstable fine grained soils where hole collapse is a possibility. Stone is dumped into a hopper at the top of the tamp. As the tamp compacts and is raised, stone empties into the bottom of the hole.

Most installers provide the client with a turnkey installation including engineered design, installation, and testing. Bradford has used aggregate piers on multiple projects, saving our clients both cost and time.